Your Vision

Our Creation

- …

Your Vision

Our Creation

- …

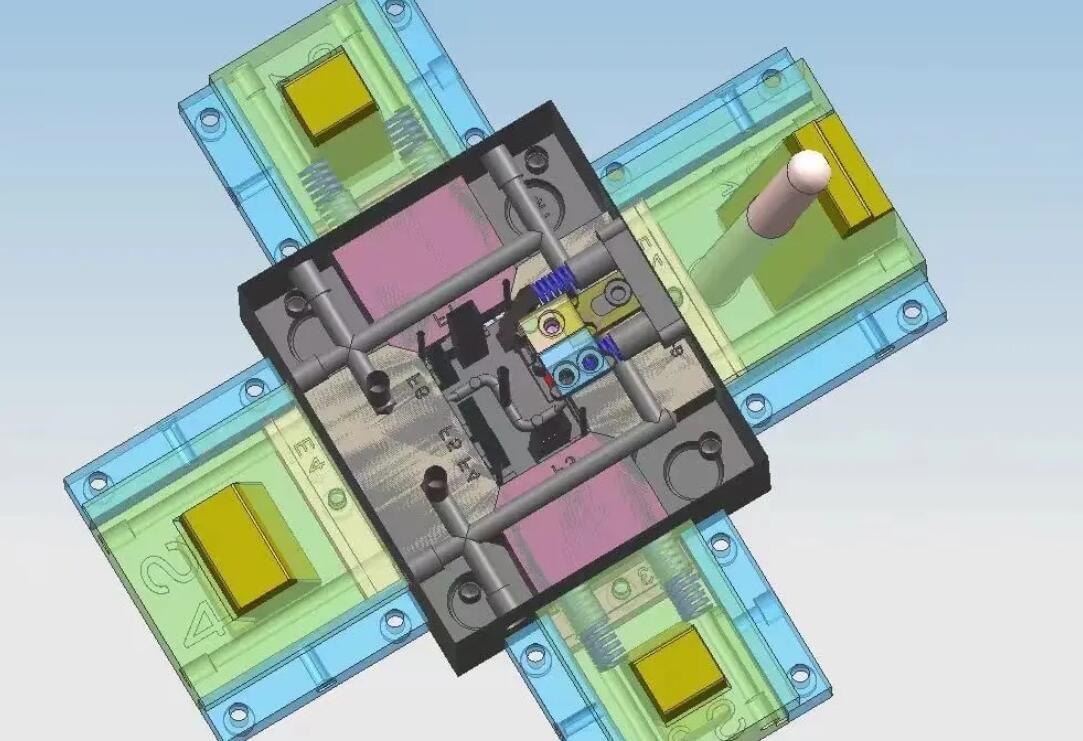

Mold Design and Manufacturing

One-stop electronic product customization!

Mold Design and Manufacturing

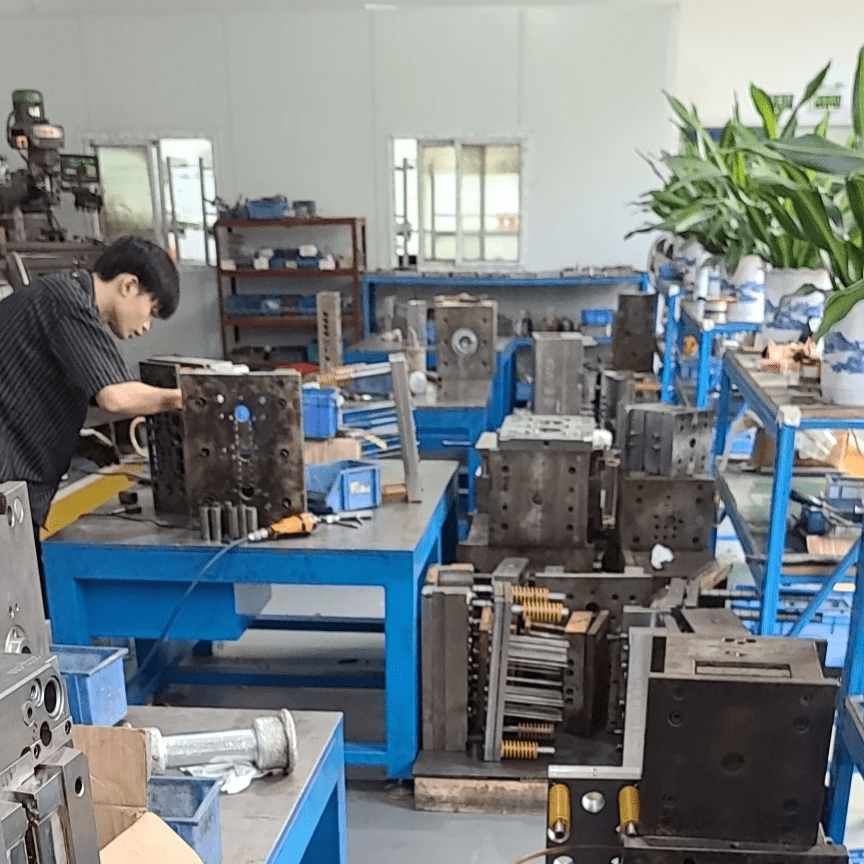

Mold production stands as a critical component in ensuring product quality and success at Shenzhen MHC, whether we are working on a customized car black box, home alarm security system, spy hidden camera, fishing camera 4K, car cooling cup, or hunting spotlight. Our advanced mold center features CNC machining centers, high-speed CNC milling machines, CNC spark machines, CNC wire cutting machines, and other precision equipment. We manage the entire mold design and manufacturing process independently, including material selection, stamping, welding assembly, and surface treatments.

Our streamlined process typically spans 60 working days, underscoring our commitment to precision and efficiency across all product categories.

1Drawing Inspecting

2Prepare Material

3Processing

4Mold Frame Processing

5Mold Core Processing

6Mold Electrode Processing

7Die Parts Processing

8Inspection

9Assembly

10Fit

11Mold Trial

12Production

Mold Design

Mold designers design molds based on customer needs and product requirements. The design includes product shape, size, material, etc.

Manufacturing Stage

Prepare the required mold materials according to the design drawings, and perform rough and finish machining on the mold materials, including milling, drilling, polishing, grinding, etc., to ensure the accuracy and surface quality of the mold.

Assembly and Debugging

Assemble the processed mold parts, check the fit of each part, and debug to ensure the normal operation of the mold.

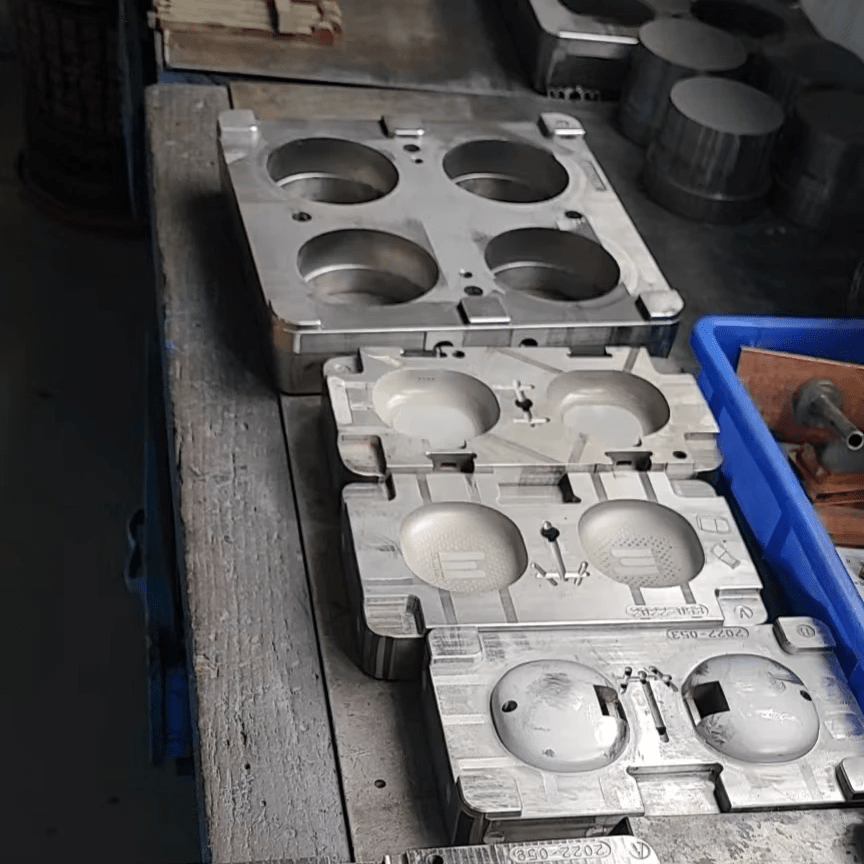

Mold Trial Stage

Install the assembled mold on the injection molding machine, fix and adjust it. Use plastic raw materials to conduct trial mold production, observe the molding of the product, and check whether there are any defects or undesirable phenomena. According to the trial mold results, make necessary adjustments and optimizations to the mold to improve product quality and production efficiency.

Acceptance Stage

Carry out a comprehensive quality inspection on the mold, including dimensional accuracy, surface quality, fit, etc. After passing the acceptance inspection, formal production will be carried out.

Mass Production

After the above process is completed, if there are no problems, mass production will begin. After production is completed, the final product will be inspected and properly packaged.